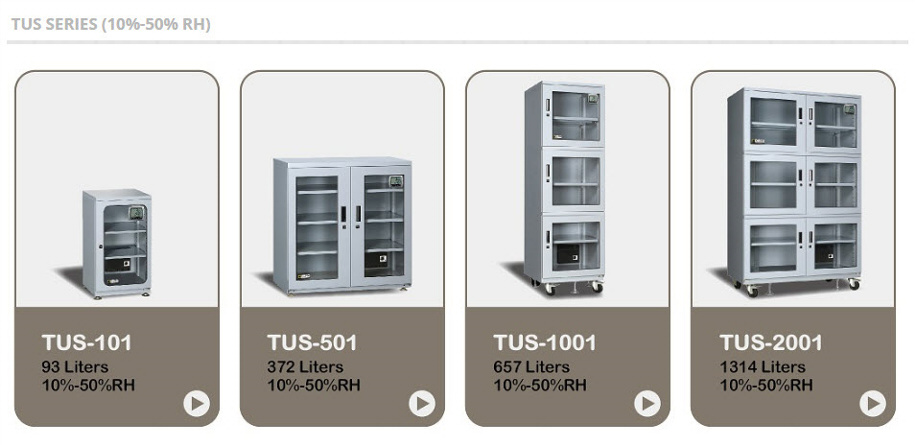

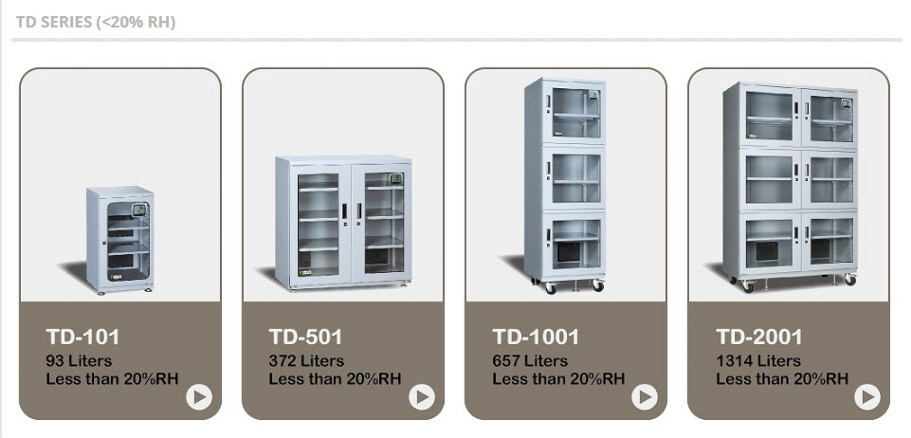

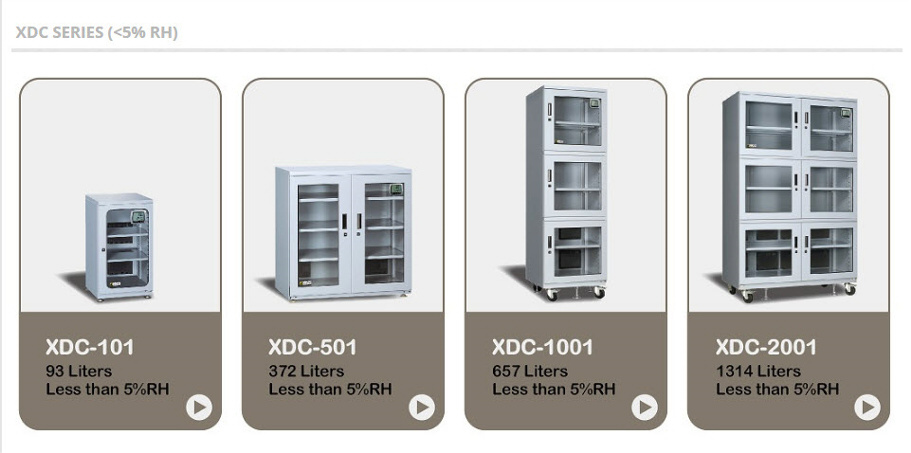

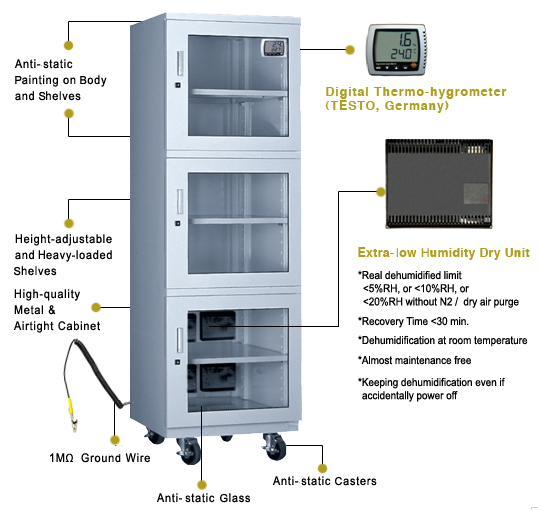

![]() Eureka Dry Tech's Fast Super Dryer dry cabinets provide automatic relative humidity control of <5% RH, <10% RH, <20% RH and user adjustable 10%~50% RH storage environments with fast recovery times at NTP condition without using N2/dry air purging. Increase product quality, reliability and yield rates by solving trace moisture problems. Eureka's Fast Super Dryer are widely used in R&D, high-tech & electronic manufacturing industries, laboratories, clean rooms, warehouse, etc.

Eureka Dry Tech's Fast Super Dryer dry cabinets provide automatic relative humidity control of <5% RH, <10% RH, <20% RH and user adjustable 10%~50% RH storage environments with fast recovery times at NTP condition without using N2/dry air purging. Increase product quality, reliability and yield rates by solving trace moisture problems. Eureka's Fast Super Dryer are widely used in R&D, high-tech & electronic manufacturing industries, laboratories, clean rooms, warehouse, etc.

Moisture sensitivity in Surface Mount Technology (SMT) is a constant problem as the industry utilizes high temperature reflow process. Many serious manufacturing defects and failures may not show up until the product is in the field are resulted from improper storage and handling of moisture sensitive components and PCBs during the assembly process. Without proper moisture control, field failures will occur. These are important factors for manufacturing industries where product reliability must be tightly controlled such as automotive, defense, medical devices, aeronautics & aviation industries.

As development cycles shorten, invention of ever-smaller device, innovative use of new materials and larger wafer chip development, all contributing to a rapid increase of moisture-sensitive devices and higher levels of trace moisture sensitivity during reflow process. Internal component damage due to trace moisture expansion, will result in MSDs during surface mount reflow process. Storing moisture sensitive devices (MSD) and components in Eureka Dry Tech's Fast Super Dryer JEDEC Dry Cabinet will provide extended floor life and will prevent moisture expansion, popcorning, intermetallic growth, oxidation, solderability and other moisture related problem from occurring in the first place.